Solar Plastic Molding

Our solar plastic molding systems use solar heat from heliostats to make plastic parts, instead of expensive fossil fuel. Energy for mold rotation is supplied by integrated PV panels.

SRM allows for zero pollution, low-cost, and very high quality molding of large plastic products like water tanks.

Water tanks are molded of FDA-compliant, food safe resins, and plastic is never burned, only warmed to a safe melting temperature.

SRM is protected by US and international patents.

Rotational molding is a globally-used technique for making large plastic objects. Over 3.6 billion pounds of plastic are rotationally molded each year. Unfortunately, the process is energy intensive and uses non-renewable energy sources like natural gas and kerosene. Over 18.4 trillion BTU of fossil fuel is consumed by the rotational molding process, generating over 2.15 billion pounds of greenhouse gasses annually.

Rotational molding is an excellent way to make large, life-improving products like water and septic tanks, boats, docks, toys, and much more. Solar Rotational Molding helps this global process cheaper to operate and much more sustainable.

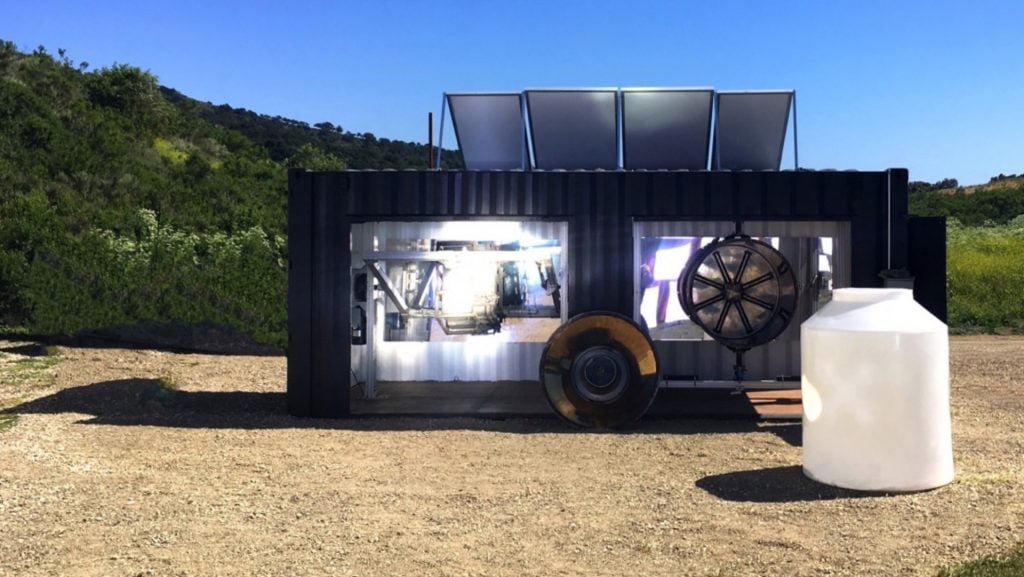

LightManufacturing’s patented SRM (Solar Rotational Molding) process uses sun-tracking mirrors called heliostats, to concentrate solar energy on a rotational mold. We have developed a uniquely capable heliostat, called the H1. Heat from the sun directly warms the mold, melting the plastic. Because the process uses heat directly in the molding process, the system is highly efficient: 75% efficient as compared to typical photovoltaic efficiency of 15% or less. There’s no need to convert light into electricity, nor does energy have to be transported via expensive transmission lines to market.

Zero pollution is generated in SRM, and all fuel costs are eliminated.

Rotational molding, and Solar Rotational Molding (SRM) can use a variety of plastics – including virgin (new) material, and recycled material. Plastics made from fossil fuel sources have many environmental issues, but the longevity and reliability of rotationally-molded plastic parts can make them compelling ‘green’ choices over the life of the product – particularly if some recycled content is used. Note that metal, wood or other materials have their own environmental issues as well.

So while plastics aren’t perfect, they have a lot to offer in the context of big long-lasting objects like water tanks, boats, furniture, and more. We think that single-use ‘ephemeral’ plastics are VERY problematic, and we are exploring ways to up-cycle some of these materials into long-lasting rotomolded products.

[ A great podcast about the issues of single-use plastics is “Waste Land” by Planet Money. Again we’d point out that we think water tanks, kayaks, septic tanks and similar big durable products are quite different in benefit and impact than (for example) disposable plastic toys given away in a fast food kids meal. ]

Solar Rotational Molding is an excellent way to close the loop and reuse post-industrial and post-consumer plastic for new products. Especially important is our ability to recycle materials in the field – near landfills and beaches – without requiring plastic waste to be transported to centralized processing facilities. The cost of transportation makes most plastic recycling uneconomical.

By removing energy costs from the molding process, SRM makes the molding of ANY plastic more sustainable and affordable, while reducing greenhouse gas and particulate emissions. New plant-based plastics may offer a source for more sustainable high performance, rotationally-molded plastics. SRM applies Concentrated Solar Power / CSP to a globally-deployed industrial ”smokestack process”, and converts it into a sustainable manufacturing process – a cleantech ‘good citizen’.

SRM™ (Solar Rotational Molding) is a patented process, with rights held by LightManufacturing Inc. who developed the technology. SRM systems are not available in kit form, and they are not public domain. We work with NGOs and non-profits, as well as government entities and commercial partners. Contact Us with your project, we’d like to learn more.

Solar Rotational Molding Systems install into areas as small as 60′ x 60′ (3600 ft2). However, most of this area is unmodified; it can be left as unimproved land, or even planted with low-height crops. Here is how the land is used:

Heliostat array footprint @ 60′ x 10′ (600 ft2)

Target enclosure footprint @ 20 ‘x 8′ (160 ft2)

Raw materials, tools, and finished part storage (typical) 300 ft2

Total: 1060 ft2 So, just 30% of the 3600 ft2 total area is occupied by objects. The balance of the land remains unchanged. Compared with the concrete-slab required to support a traditional rotational molding operation, SRM offers a far less impactful solution. Large SRM systems scale as big as needed – 12 systems pack into a single acre of land.

Most people think of injection molding when they think of plastic manufacturing – this process is very capital intensive, and produces high volumes of relatively small, thin-walled objects – i.e. plastic cutlery, small toys, flashlight bodies, etc.

Rotational molding is best at making relatively large objects – from something 6″ across to very large objects such as 8′ diameter water tanks or 10′ long boats, with walls up to 1″ thick. These large, heavy objects do not pack efficiently, and shipping them is essentially to ‘ship air’. As a result, Rotational Molding is distributed across all markets – European Rotomolders making parts for Europe and for export, Asian rotomolders making parts for Asia and for export, etc. The distributed nature of rotational molding allows LightManufacturing’s SRM process to be deployed as needed in solar-rich regions.

Any rotational molding resin can be molded using SRM, including polyethylene, polypropylene, nylon, and other polymers. The SRM process uses CSP / Concentrated Solar Power to achieve any desired molding temperature, and often with cycle times less than ordinary rotomolding. Contact us to learn how we can help convert your traditional operation to a low-cost, sustainable manufacturing operation.